Dillsburg, PA. Monday May 1, 2023.

It’s been a busy year since our last post! (Sorry its been so long). We were so inspired by Murray Hallam’s Aquaponics Design Course that my wife Kristi and I built a custom version of his Indy 11.5 Aquaponics System in our backyard.

Hoop House

It all started in May 2022, when I dug out and leveled a 30 foot by 18 foot foundation for a high tunnel greenhouse. I followed guidelines from Bootstrap Farmer to build a 16 foot by 28 foot hoop house using chain link fence posts and top rails. (My neighbor Steve helped me drive the posts and bend the hoops). The hoops are covered with 6 mil green house plastic. (Two layers in winter). The plastic is fastened to the hip boards and baseboards with wiggle wire and tracks.

Fish Tank and Filters

The fish tank is a used 330 gallon IBC Tote (with a few inches cut off the top). There are two 55 gallon plastic drums for the swirl filter and mineralization tanks. These were placed into the greenhouse before the end walls were constructed .

We purchased 30 Tilapia fingerlings from Lakeway Tilapia for the fish tank. Along with their starter food Pro Pack. “Each Pro Pack contains the exact amount of tilapia food necessary to raise tilapia fingerlings from one inch through six inches long.”

Free Wood

New Hope Ministries in Dillsburg, PA hosts a food pantry were customers can shop for items they need free of charge. The pantry offers fresh produce and has coolers. Kristi and I were led by the Holy Spirit to volunteer there and donate produce from the Aquaponics greenhouse. Across the street is a big sign that reads “Free Pallets”. I found enough wooden shipping crates there made of plywood and 2×4 lumber to build both of the grow beds!

I used SketchUp to design two 4 foot by 16 foot grow beds using the dimensions of the salvaged lumber. The crate bottoms became the bottom of the grow beds and the crate sides became the sides of the grow beds. And the 2×4’s are the legs and cross braces.

Grow Beds

The Indy 11.5 has 4 separate 4 foot by 8 foot grow beds. The grow beds and the sump are all lined with Duraskrim, a 20 mil thick food grade reinforced plastic. Two of these are Media beds. One is a Deep Water Culture (DWC) bed. And one is a Wicking bed.

The Media beds are flood and drain systems filled 10 inches deep with 3/4 inch gravel. Water is continuously pumped into the beds and an auto siphon (or bell siphon) drains the bed into the sump below when it gets 8 inches deep. The gravel provides a strong foundation for larger plants like broccoli, kale, and peppers. We also use it for cut and come again plants like spinach, arugula, basil, cilantro, and leaf lettuce. I designed a 10 inch deep trough under the media beds for the sump. The sump is insulated underneath with 1 1/2 inch Styrofoam.

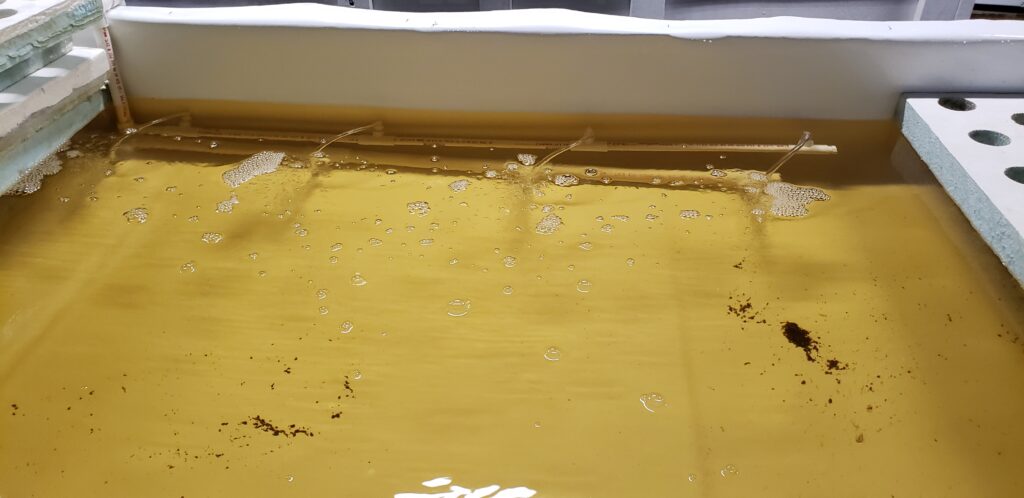

The Deep Water Culture (DWC) bed is our lettuce factory where we grow 24 plants per week on 2 inch thick floating rafts. There are 5 24-hole rafts and 2 36-hole rafts. When seedlings are one or two weeks old they are transferred from the cell trays into net pots in the 36-hole rafts. After another week or two the seed starting media is cleaned off the roots and they are transplanted into Grow Grips and placed into a 24-hole raft. Water is pumped into the DWC through Infusinator venturi valves to provide aeration and flows out back to the sump. An adjustable stand pipe keeps the water level at about 10 inches deep.

The Wicking bed is self watering and is ideal for growing root vegetables like carrots, beets, radishes, potatoes, and parsnips. It has a 4 inch deep vermiculite base that acts as a water reservoir. A 4 inch slotted fill pipe runs the length of the bed. A sheet of weed mat separates the vermiculite from the coco coir, compost, and vermiculite grow media. Water moves to the surface by natural capillary action. (The water does not return to the sump from the wicking bed).

Free Water

When all the components are filled with water the system holds about 1000 gallons. To fill the system initially and to provide water to top up the sump when it gets low we setup three 55 gallon drums to collect rain water from the roof of our house. A 3/4 inch potable water pipe was buried under ground to connect the rain barrels to a float valve in the sump. When the sump water level drops to within about an inch above the water pump the float valve opens to allow water to flow into the sump from the rain barrels. I found the Little Giant Plastic Trough-O-Matic Float Valve at Tractor Supply.

When It’s Cold Outside

The winters in Central Pennsylvania get cold. The summers are warm and humid, the winters are very cold and snowy, and it is partly cloudy year round. Over the course of the year, the temperature typically varies from 23°F to 86°F and is rarely below 11°F or above 94°F.

Heating is provided by four AQQA 800 Watt Aquarium heaters in the fish tank. These maintain the fish tank at 78 degrees Fahrenheit. The sump will be about 71 degrees in the morning after a cold night.

A second layer of plastic is added to the hoop house to increase insulation in the Winter. There is an inflation blower that pumps dry outside air into the gap between the layers. This more than doubles the insulation (R) value of the plastic covers.

Air Ventilation and Circulation

There is one Exhaust fan on a thermostat in the West end wall above the door. This is the second time we have used the iLiving – 24″ Wall Mounted Exhaust Fan with Automatic Shutter. On a sunny day the greenhouse quickly reaches 80 – 85 degrees Farenheit. The exhaust fan turns on at about 90 degrees and will cool the greenhouse down to 72 degrees (assuming it is this cool or less outside).

In the Winter, I also roll up the plastic on the West facing door (our prevailing wind is from the West Northwest) to allow dry air to circulate inside. There is a louvered vent above the East door that will open automatically when the exhause fan comes on and I also prop it open in the Winter to allow natural airflow.

There are two cSimple Deluxe 18 Inch Industrial Wall Mount 3 Speed Commercial Ventilation Metal Fans one above each grow bed. These are turned on manually, usually in the morning to dry off the plants. When the humidity get too high these are also used to circulate air and help move it our of the greenhouse through the end wall vents.

During the warmer months the second layer of plastic is removed from the greenhouse and the sides are rolled up halfway to allow natural air circulation. The bottom half of the sidewalls are covered with screen to prevent bugs from coming in. The doors are also covered with screen so the plastic can be removed.

Air Pumps and Air Stones

There are three Tetra AP 300 Whisper® Deep Water Air Pumps. I love these pumps because they are very quiet and provide good aeration to the bottom of the fish tank and mineralization tank. They also provide an inexpensive repair kit to replace the internal rubber diaphragms and working parts to extend the life of the pump. I’ve had five pumps in various systems running outside in a greenhouse (summer and winter) continuously for over 6 years. The air stones we use are medium pore 1-1/2″ by 0.75″, 0.35 cfm Sweetwater AS8S air stones, from Pentair Aquatic Eco-Systems. Medium pore air stones combined with the AP 300 air pumps are the most economical for the amount of air these systems need. The tubing from the distribution manifold to the air stones to the AP 300 is black vinyl 3/16″, (AES # BTP30HD).

Fish Tank Aeration Backup System

We learned how to make a simple aeration backup system for the fish tank when the main electricity grid goes off from Murray Hallam’s Aquaponics Design Course. The system pumps water from within the fish tank and sprays it onto the top. This breaks the surface and circulates the water. Our backup system is made from a 12V DC Rechargeable LiFePO4 Lithium battery, a Rule bilge pump, a Rule float switch, a plastic box, a Uniseal, a short piece of PVC pipe, two lengths of 3/4″ vinyl tubing, a couple hose clamps, a valve, and a 90 degree elbow.